Pre-tensioning and measure

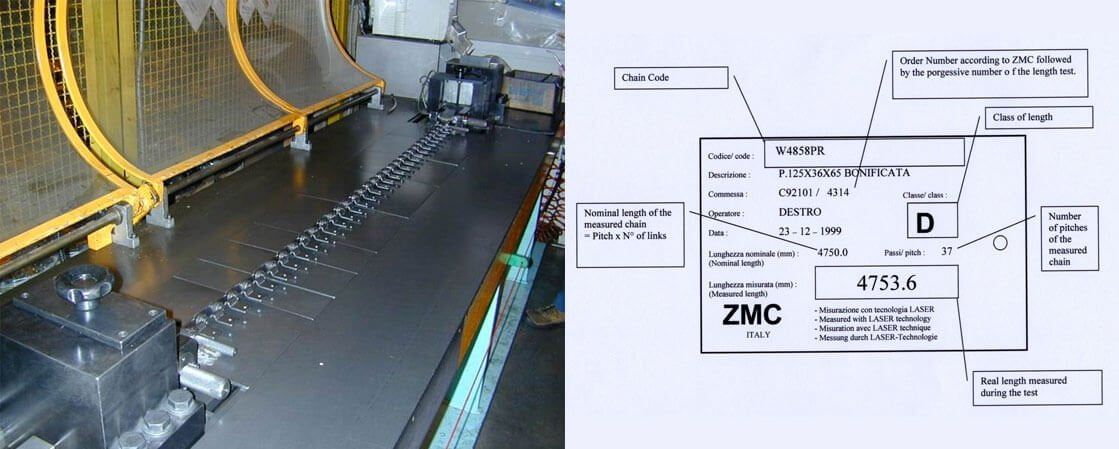

On request, ZMC provides individually pre-tensioned and measured chains with an specially designed tool that uses laser technology and the application of a controlled tensile force.The first stage, called pre-tensioning, provides for the application to the chain of a tension equal to 30% of the nominal breaking load. The pre-tensioning allows initial chain tension adjustment for the running in of the chain.The actual measurement is then performed by reducing tension to 2% of the breaking load, as required by ISO 1977 standard.For each test a label is printed and secured to the chain. The following details are reported on the label:

- The measured length

- The type of the chain and of the test, and a letter which can be traced back to the tolerance class in which that particular strand of chain falls. Given that the tolerance of length on the conveyor chains is always more than the nominal length, it is divided into intervals of 1mm width. This means that all the chains with a length between the nominal value and 1 mm more will show the letter A on the label, those from 1mm to 2mm longer will report the letter B, and so on. This system is meant to facilitate, during assembly on the system, the pairing of chains with similar lengths.