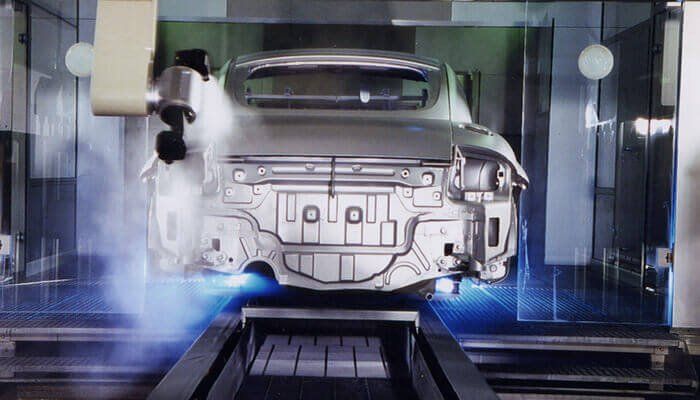

Transport chains for the automotive industry

ZMC conveyor chains are present in the plants of all main car manufacturers worldwide.

The chains for floor or overhead operation are used in all the main stages of the production for the process of: cars, vans, trucks, tractors and buses or their components.

The technical solutions for this sector designed by ZMC according to customer specifications or in collaboration with the latter are almost endless. The innovation of our products continues unabated with the aim of improving: performance, reliability and durability. The chains for the automotive sector are called upon to meet evolving needs both from a technical point of view and in other aspects held in ever-increasing consideration by conveyor manufacturers and end users, such as: the reduction of maintenance costs, the energy saving and respect for the environment.

For various applications, chains in self-lubricating or low-maintenance versions are available.

Among the most typical and successful uses of ZMC chains in the automotive sector, we offer:

- floor conveyors for handling of car bodies or complete cars supported by a skid frame in various stages of the production process (welding, bodywork, assembly, saddling, final check)

- overhead lines with biplanar chains for transporting components (eg doors)

- overhead lines, accompanying systems, elevators and descenders (chains with pushers and articulated coupling mechanisms)

- buffer lines (chains with fly rollers) for storage systems of car bodies or components

- conveyors for protective pretreatment of car bodies (pendulum systems for cataphoresis and phosphating)

- caterpillar drive systems (chains with shaped teeth)

- paint-shop conveyors

- paint-shop drying ovens (exclusive self-lubricating version ZMC with maximum operating temperature 250 ° C)

- mono or bi-slat conveyors for ground transport (on request, the 400 to 4000mm wide slats can be included in the supply)

- conveyors for watertest of cars